- 产品参数

- 图文介绍

- 企业简介

- 企业地址

一、 概述

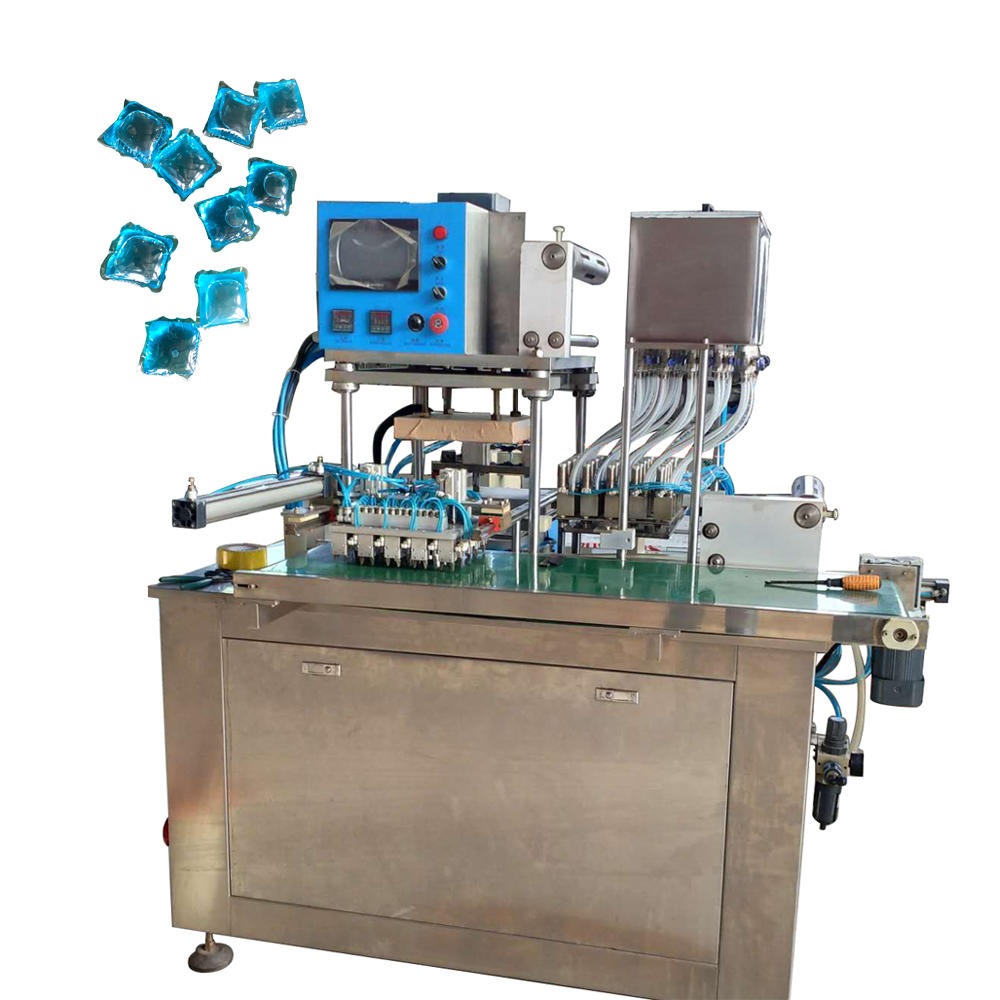

全自动铝塑铝铝泡罩包装机,该机是本公司综合国内外铝塑包装机的优点进行创新设计,与药品接触部分采用不锈钢以及 次铝合金材料制作,适用于制药、食品、保健品行业包装素片、糖衣片、胶囊剂,亦可包装番茄酱、巧克力酱、蜂蜜等。

该机是我国药品包装进行技术改进和实施GMP生产的设备,产品己远销国内外各大药厂和大、中型,并出口二十多个国家与地区,深受客户青睐与致好评。

二、全自动铝塑铝铝泡罩包装机性能特点

1.变频无级调速、机械牵引;

2.行程可调,调节范围为40-180mm,调节方便,同步准确;

3.标准配备四工位(成型、热封、压痕、冲裁)并每工位安装四根立柱,调节更加方便、运行稳定;

4.采用板式模具、正压成型、批号、压痕切线、铝箔/铝铝自动放发;

5.配置一套加料器,其充填率高达99.5以上;

6.该机体积小、重量轻、调节与维护空间等优点。

7.采用触摸屏PLC控制,操作方便

三、全自动铝塑铝铝泡罩包装机主要技术参数

项目 |

参数 |

冲裁频率 |

铝塑:10-40次/分钟 |

铝铝:10-30次/分钟 |

|

行程可调范围 |

40-160mm(可调) |

成型面积 |

120×90mm |

成型深度 |

26mm(可以根据客户要求特制) |

主电机功率 |

1.5kw |

上加热功率 |

0.5kw |

下加热功率 |

0.5kw |

热封加热功率 |

0.5kw |

气泵容积流量 |

0.2m2/min |

气泵气压 |

0.4-0.6Mpa |

PVC |

0.25-0.5×130mm |

PTP |

0.02-0.035×130mm |

透析纸 |

50-100g×130mm |

外型尺寸 |

3000×730×1600 mm |

整机重量 |

约1000kg |

一、 Description

multifunctional automatic aluminum (aluminum) bubble cap packing machine, the machine is the company comprehensive domestic and foreign aluminum plastic packaging machine has the advantages of innovative design, the contact part of the drug and by stainless steel and high grade aluminum alloy materials production, applicable to the pharmaceutical, food, health care products packaging industry plain tablets, sugar coated tablets, capsules, can be packaged tomato sauce, chocolate sauce, honey and so on

The machine is China pharmaceutical packaging technology improvement and implementation of GMP production equipment, the product has been sold to domestic and foreign pharmaceutical companies and large and medium-sized hospitals, and exported to more than 20 countries and regions, favored by customers and praise.

二、Performance characteristics

1.Frequency conversion stepless speed regulation, mechanical traction

2.Adjustable stroke, adjustable range of 30-100mm, convenient adjustment, accurate synchronization

3.Standard is equipped with four stations (molding, heat sealing, indentation, punching and cutting) and each station to install four posts, the adjustment is more convenient, stable operation;

4.The use of plate mold, positive pressure molding, batch number, indentation tangent, aluminum foil / aluminum automatic discharge;

5.The configuration of a set of universal feeder, the filling rate is as high as 99.5;

6.The machine has the advantages of small size, light weight, adjustment and maintenance space, etc.

三、Main Technical Parameters

PROJECT |

PARAMETERS |

Cutting Ffequency |

Al-plastic:10-40Times/min |

Al-Al:10-30Times/min |

|

Travel Range |

30-100mm (Adjustable) |

Max forming area |

120×90mm |

Max Forming Depth |

20mm( customized according to customer requirements) |

Main motor power |

0.75kw |

Upper heating power |

0.5kw |

Lower heating power |

0.5kw |

Heat sealing heating power |

0.5kw |

Air volume flow |

0.2m2/min |

Air pump pressure |

0.4-0.6Mpa |

PVC |

0.25-0.5×130mm |

PTP |

0.02-0.035×130mm |

Dialysis paper |

50-100g×130mm |

Overall dimensions |

2070×650×1060 mm |

Weight |

About560kg |

-

-

-

-

-

FRS-200C 高速筛片机 上旋式筛片机 小型筛片机¥1.80万

FRS-200C 高速筛片机 上旋式筛片机 小型筛片机¥1.80万 -

-

-

- 产品参数

- 图文介绍

- 企业简介

- 企业地址