- 产品参数

- 图文介绍

- 企业简介

- 企业地址

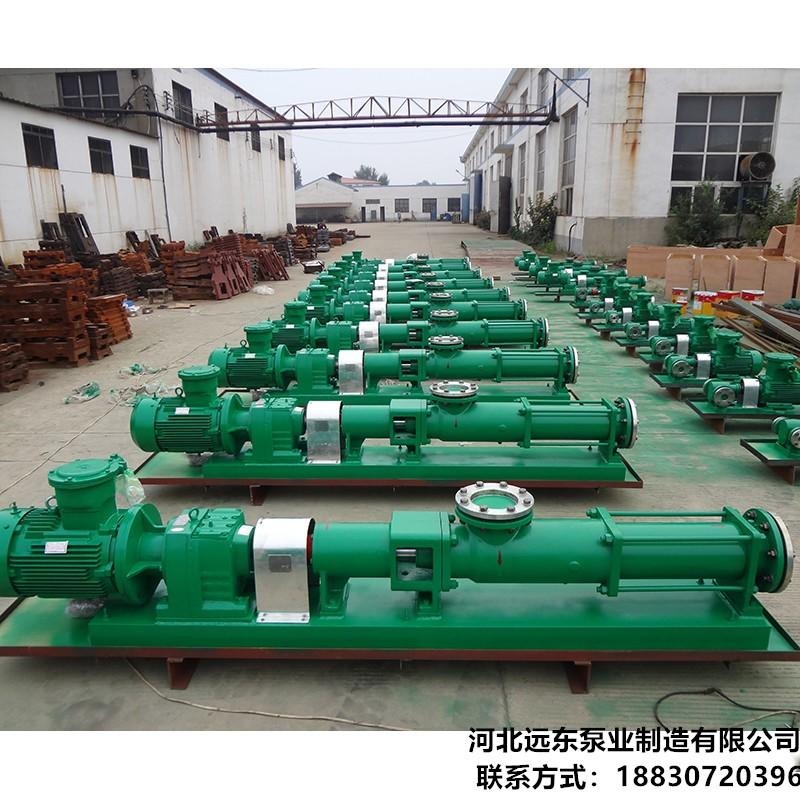

输送水泥浆泵用G40-2V-W112单螺杆泵配YCJ减速机性价比高可用污水专用泵 石灰膏泵-泊远东 河北远东泵业制造有限公司坐落于铸造名乡—河北省泊头市。公司占地面积38650平方米,建筑面积20300平方米,是国内的集设计、铸造、生产、销售、服务于一体的容积泵专业制造厂家。公司始建于1984年,有二十几年专业研制经验。目前产品设计采用国际先进水平实体设计软件;产品研发、制造、检验、交付按照ISO9001质量管理体系控制过程质量;产品制造广泛使用加工中心、数控机床、专用精机、高精设备;检测设备拥有显微镜、渐开线检测仪、光学投影仪、测齿仪、脉冲辉光离子氮化炉等大型检测设备,并建有国家B级试验站。本厂以的产品水平、优质的售后服务、恪守信用而在市场上倍受欢迎,产品不衰,赢得了用户的普遍赞誉。公司已通过ISO9001:2000国际质量体系认证,中国船级社CCS型式认证,法国船级社BV产品工厂认证,美国船级社ABS产品质量认证,中国渔业船舶检验局船用泵认证,成为中石油物资资源市场成员、中石化物资资源市场成员。河北省知名产品生产企业,船用泵产品承制企业。

河北远东泵业制造有限公司坐落于铸造名乡—河北省泊头市。公司占地面积38650平方米,建筑面积20300平方米,是国内的集设计、铸造、生产、销售、服务于一体的容积泵专业制造厂家。公司始建于1984年,有二十几年专业研制经验。目前产品设计采用国际先进水平实体设计软件;产品研发、制造、检验、交付按照ISO9001质量管理体系控制过程质量;产品制造广泛使用加工中心、数控机床、专用精机、高精设备;检测设备拥有显微镜、渐开线检测仪、光学投影仪、测齿仪、脉冲辉光离子氮化炉等大型检测设备,并建有国家B级试验站。本厂以的产品水平、优质的售后服务、恪守信用而在市场上倍受欢迎,产品不衰,赢得了用户的普遍赞誉。公司已通过ISO9001:2000国际质量体系认证,中国船级社CCS型式认证,法国船级社BV产品工厂认证,美国船级社ABS产品质量认证,中国渔业船舶检验局船用泵认证,成为中石油物资资源市场成员、中石化物资资源市场成员。河北省知名产品生产企业,船用泵产品承制企业。

公司以“泊远东”牌齿轮泵,螺杆泵为主导产品,涉及21个系列,4200多种规格,年生产能力达43000多台(套)。产品行销油田、化工、电力、船舶、冶金、食品等各大行业。产品除满足国内客商的需求外,部分出口至东南亚、美洲、欧洲等国家和地区。公司在设有30多个分支机构,并建立了完善的营销服务网络,拥有一支庞大敬业的营销服务队伍,可为广大客户提供优质的服务。 公司以严谨的质量体系、先进的生产设备、完善的检测手段、丰富的制造经验、务真求实的远东团队,来有效保证产品质量。以满腔真诚期待与国内外各界人士携手铸就多方共赢的辉煌。

我公司是一个生产齿轮油泵和螺杆泵的专业公司。公司拥有各种设备80台,主要设备有:C6140 CW6163C车床24台,TX611C/4镗床2台,M131M7130磨床8台,C125A立车2台,Y318K Y3150E滚齿机6台,E3050X16/1摇臂钻床2台,E5163立式钻床2台,B1-400铣床3台,螺杆泵转子专用QH2-007铣床1台,半自动螺旋转子QH2-029B铣床2台,X53K立铣3台,半自动螺旋转子QH2-031 QH2-032磨刃机台。

我公司拥有省计量局制试验台1台,自制试验台3台,使生产产品从原材料投入到产成品出厂实现了全过程检测。产品出厂合格率 % ,具备较强的综合配套制造能力。理化试验室、长度计量室是国家计量确认合格单位,使产品从原材料投入到产成品出厂实现了全过程检测。产品出厂合格率% ,具备较强的综合配套制造能力,公司年可生产各种泵 6000 多台。

运费说明:

1.本公司常规产品1-3天发货,特殊要求或者需定做的产品发货时间已与客户协商为准, 2.泵运费方式有两种:快递和物流.小泵和小型配件发快递,其余体积较大,数量较多,推荐走专线物流货运,一般南方,中部地区及沿海地区3-5天左右到达.西部,北部较远的地区以及少数二次中转地区5-8天左右可到,具体覆盖范围请咨询公司客服人员.安装使用:请您根据产品说明书的步骤进行操作,如有问题,请联系我公司.为了保护您的利益,我们已经提醒客户在收到货物时,要开箱验货,如在打开验货时发现货物丢失,损害或者不符,请拒签收,您签收就代表已准确无误的收到后屋,若在签收货物之后才发现货物丢失或者不符,如不负责. 客户收到货后,产品无法安装或者规格有误,本公司提供退货或者换货服务,退货或者换货的客户请保证货物的完好无损,并承担往返运费. 客户收到后,如果产品存在质量问题,请在收货后7天内联系我公司,提供相关质量问题图片,我公司将在时间给您退货或者换货,因为我公司已经在发货前已经仔细检查过,所以过期将不提供此项服务,还请谅解.

●应用:

该螺杆泵可用于输送中性或腐蚀性的液体,洁净的或磨损性的液体,含有气体或易产生气泡的液体,高粘度或低粘度的液体,包括含有纤维物和固体物质的液体.

G型单螺杆泵系列,是我厂主要系列产品,应用极为广泛.

GS系列泵是由G型基本系列发展来的,区别在于特殊的泵体,"S"的意义是快速清洁,每个零件的任一细小部位都能被清洁得非常干净.

食品业:用于酒厂输送酒,废渣及制酒流程中的投配料的输送.

纺织业:用于输送合成纤维,黏胶液,染料,油墨,尼龙粉液.

造纸业:用于纸浆黑液的输送.

石油业:用于多种油类,油脂产品的地面集输泵.

化工业:用于输送各种悬浮液,乳胶业,酸,碱,盐液.

造船业:用于输送渣油,扫舱和污水,海水等.

建筑业:输送灰浆,灰膏.

核工业:输送带颗粒的放射性液体. 电厂:用于水煤浆的输送 .

●G型单螺杆泵设计特点:

1.联轴器两端采用一字销万向节接头,其销子和销套是由特殊材料制成的,因而其寿命得到了很大的改

善,其结构简单容易拆卸见.

2.衬套两端有包过来的橡胶使其与进出管联接处密封可靠从而保证了衬套体不受到腐蚀

3.在吸入管和轴承体之间装有一个可进行更换的填料箱,既能用于填料密封又能用于机械密封(可进行

不同形式的密封更换).

4.GS 系列吸入管和压出管的联接是标准DIN1187-A的螺纹联接,可以快速拆卸吸入和压出两侧的管子

和软管

单螺杆泵由于结构和工作特性Single screw pump due to the structure and working characteristic

与活塞泵离心泵、叶片泵、齿轮泵相比具有下列诸多优点:Piston pump and centrifugal pump, vane pump, gear pump compared with many of the following advantages:??? 1、能输送高固体含量的介质;1, the transmission of high solid content of media can;2、流量均匀压力稳定,低转速时更为明显;2, flow uniform pressure stability, low speed is more obvious;3、流量与泵的转速成正比,因而具有良好的变量调节性;3, flow is proportional to the pump speed, thus has a good regulatory variables;4、一泵多用可以输送不同粘度的介质;4, a multi-purpose pump can transport different viscosity of medium;5、泵的安装位置可以任意倾斜;5, the installation position of the pump can be arbitrary oblique;6、适合输送敏感性物品和易受离心力等破坏的物品;6 items and the centrifugal force, etc, is suitable for conveying sensitivity damage items;7、体积小,重量轻、噪声低,结构简单,维修方便。7, small volume, light weight, low noise, simple structure, easy maintenance.

选用泵的规格是根据被输送液体的性质和流量、压力来决定的,而泵的转速则由输送液体的粘度和腐蚀性、作为主要参数来选择,才能保证泵可靠运行。Choose the specifications of the pump is according to the nature of the liquid to be delivered and decide the flow, pressure, while the pump speed by conveying liquid viscosity and corrosive, as the main parameter to select, to ensure the pump running.泵的设计转速为输送清水或清水相类似的无腐蚀性液体时允许高转速,在实际使用中因介质性质与寿命要求不同,选用时一般都应低于设计转速。Design speed of pump for conveying water or similar without corrosive liquid to allow the highest speed in the water, in be used actually due to the different requirements, dielectric properties and service life when choosing generally should be lower than design speed.对高粘度和含颗粒介质,一般采用设计转速的1/2-1/3或更低些,低转速对泵的磨损有利,但在使用后由于定子的磨损流量下降,这时可适当提高转速,以补偿流量下降也为常策。For high viscosity and particle medium, generally USES the design speed 1/2 - a third or more lower, low speed of pump wear and tear, but after use due to the wear and tear of the stator flow down, then can be appropriately increased speed, to compensate for declining to often.输送介质的温度应在-10℃~80℃特殊情况可高达120℃。The temperature of the medium should be - 10℃~ 80℃special circumstances can be as high as 120℃.

泵的每级(定子的一个导程)正常压力为0.6Mpa,短时间(不超过30分钟)内允许高达0.8Mpa,当磨损后在相同输出压力时的容积效率要逐步下降。Pump per level (lead) of the stator of a normal pressure is 0.6 Mpa, inside short time (less than 30 minutes) to allow up to 0.8 Mpa, when after wear and tear on the e output pressure volumetric efficiency will decline gradually.泵送清水时高吸程为8米,实际使用建议不超过6.5米,当泵送高粘度介质时,应以正压吸入。When pumping water to the highest suction is 8 meters, the actual use suggest no more than 6.5 meters, when pumping high viscosity medium, the positive pressure breathing.

单螺杆泵使用过程中故障及解决方法Single screw pump failure in use process and solving methods

单螺杆泵再抽一些井中的油时经常会遇到的故障:杆断脱、泵漏失、定子溶胀、定子脱胶、管漏失等,下面具体介绍下。When single screw pump some pumping Wells in the oil again often fault: rod break off and leakage of pump, and swelling of the stator, the stator degumming, pipe leakage, etc., under the specific introduction below.

1、杆断脱:由于单螺杆泵抽油杆负荷过大、磨损或误操作等原因,引起抽油杆断裂,脱扣或撸扣的情况,具体表现为:在短期内,泵效大幅度下降,动液面迅速上升,电流下降甚至接近空载电流。1, the rod break off: due to the large single screw pump rod load, wear or wrong operation and so on reasons, lead to sucker rod breaking, tripping or lu buckle, embodied in: in the short term, pump efficiency drops sharply, the working fluid level rising rapidly, current decline or even close to the no-load current.扭矩和轴向力仍为平稳直线,但由于缺少了井下泵的工作扭矩,光杆扭矩值远小于正常工作范围,轴向力缺少了液压力对转子产生的轴向力,因此也小于正常范围,根据断脱部位,杆柱自重产生的轴向力不同,据此可计算出杆柱断脱深度。Torque and axial force is still as smooth as a straight line, but the lack of the downhole pump working torque, polished rod torque value is far less than the normal scope of work, the axial force without the fluid pressure of the axial force produced by the rotor, which is less than the normal range, according to the broken parts, rod string axial force produced by self weight, can calculate the depth of the rod string break off accordingly.

2、泵漏失:由于单螺杆泵的定子橡胶磨损,造成定转子过盈减小,泵承压能力下降。And leakage of pump, 2: as a result of the single screw pump stator rubber wear, cause stator interference is reduced, the pump pressure can drop.因此,漏失量增加。Therefore, the loss increased.具体表现为:泵效逐渐下降,动液面逐渐上升,电流逐渐下降。Specific performance is: the pump efficiency is falling, working fluid level is gradually rising, the current gradually decreases.由于漏失量加大,泵有功扭矩下降,扭矩低于正常范围。Decline because of the increase amount of leakage, pump active torque, torque is lower than the normal range.由于液压力产生的轴向力下降,轴向力低于正常范围,但仍大于杆柱在采出液中的重量。The axial force generated in the fluid pressure drop, axial force is lower than the normal range, but still greater than the rod string weight in produced fluid.

3、定子溶胀:由于采出液的作用。3, stator swelling: due to the effect of produced fluid.单螺杆泵的定子橡胶发生溶胀,造成定转子过盈增加,泵效和动液面正常,电流增加,由于过盈大,定转子的初始扭矩增加,因此光杆扭矩增加,超过正常范围,严重时会造成定转子抱死,但轴向力正常。Single screw pump stator rubber swelling occurs, causing rotor interference increase, pump efficiency and working fluid level is normal, current is added, due to the interference, rotor initial torque increase, so the polished rod torque increase, more than the normal range, serious will cause the rotor, holding in death of the set, but normal axial force.??? 4、定子脱胶:定子脱胶是由于定子粘接强度不够造成。4, stator degumming: stator degumming is caused by the stator bonding strength is not enough.表现形式为泵效急剧下降,动液面上升,电流下降并波动。A sharp drop in form of pump efficiency, dynamic liquid level rise, current decline and volatility.脱胶时,泵有功扭矩为零,光杆扭矩下降很大。Degumming, pump active torque is zero, the polished rod torque decreased a lot.另外,由于脱胶后定转子之间发生不规则摩擦。In addition, because after degumming with irregular friction between stator.光杆扭矩会出现不规则液动。Polished rod torque will be irregular hydraulic.液压力产生的轴向力为零,因此,光杆轴向力低于正常范畴,但仍高于杆柱在采出液的重量。Axial force produced by hydraulic pressure is zero, therefore, the polished rod axial force is lower than the normal category, but still higher than the weight of the rod string in the produced fluid.

5、管漏失:管漏失是由于油管壁上存在裂缝造成的。5, pipe leakage, leakage of tube is caused by the tubing wall cracks exist.现象为泵效下降,动液面上升,电流减小。Phenomenon of pump efficiency drops, working fluid level rise, current decreases.由于单螺杆泵工作压差减小,泵有功扭矩下降,光杆扭矩低于正常范围,液压力产生的轴向力减小,光杆轴向力略低于正常范围,但仍高于杆柱在液体中的重量。By the pumping action of the single screw pump working pressure differential is reduced, active torque, polished rod torque is lower than the normal range, the axial force produced by hydraulic pressure decreases, and polished rod axial force is slightly lower than the normal range, but still higher than that of rod string weight in liquid.这是单螺杆泵在抽井中的油时常遇到的故障类型,在使用时一定要注意。This is single screw pump in oil Wells in the fault types often encountered, it is important to note that when using.

输送水泥浆泵用G40-2V-W112单螺杆泵配YCJ减速机性价比高

1、流量:0.2--130m3/h;2、工作压力:≤1.2MPa;使用温度:常规0--80℃,特殊材料可达120℃ ;5、粘度:1-输送水泥浆泵用G40-2V-W112单螺杆泵配YCJ减速机性价比高可用污水专用泵 石灰膏泵-泊远东

- 产品参数

- 图文介绍

- 企业简介

- 企业地址