- 产品参数

- 图文介绍

- 企业简介

- 企业地址

立式双螺杆泵V2.1ZK34Z1M1W73配2.2kw-4电机做原料油卸车泵,原料油输送泵

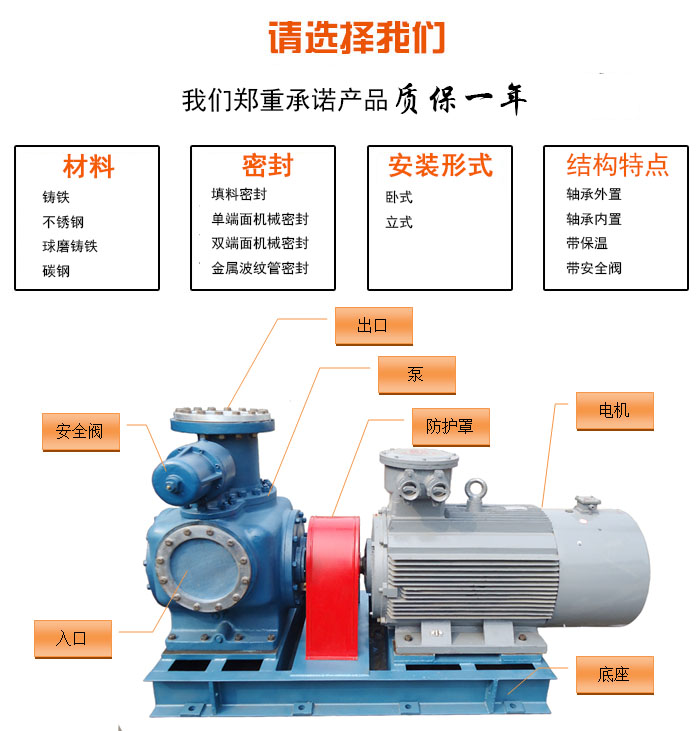

一、双螺杆泵的特点

双螺杆泵可以无搅动无脉动平平稳地输送各种介质,由于泵体结构保证泵的工作元件内始终存有泵送液体作为密封液体,所有的泵有很强的自吸能力,且能汽液混输。

双螺杆泵的特殊设计保证了泵有高的吸入性能即很小的NPSHr 值。

双螺杆泵采用独立润滑的外置轴承允许输送各种非润滑性介质。

双螺杆泵采用同步齿轮传动转动零件互不接触即使短时间干转也没有危险( 12min)。

卧式立式带加热套等各种结构型式齐全可以输送各种清洁的不含固体颗粒的低粘度或高粘度介质先用正确的材质甚至可以输送许多腐蚀性介质。

二、双螺杆泵性能范围

可输送各种不含固体颗粒的介质。

介质粘度1-1500mm2/s 降低转速粘度可到3-106mm2/s。

压力范围4.0MPa。

流量范围1-2000m3/h。

温度范围-15 -280。

三、双螺杆泵应用

造船用作船用装载泵扫仓泵船用压载泵主机滑油泵燃油输送泵燃油喷射泵货油泵等。

热电厂重油及原油输送泵重油燃油泵等。

化工用作各种酸碱盐液以及树脂颜料油墨油漆甘油石蜡的输送泵。

炼油厂用以输送各种加热油沥青油焦油乳胶液沥青及用作油轮油池油罐车等各种油品的装载及卸载。

食品用于酒厂食品厂糖厂罐头厂等输送酒精蜂蜜糖汁牙膏牛奶奶油酱油植物油动物油葡萄酒等。

性能参数的选择:

1.流量Q:

作为容积式泵,影响双螺杆泵流量的因素主要有转速n,压力p,以及介质的粘度v。The selection of performance parameters:

1. The flow Q:

As a positive displacement pump, double screw pump flow effects are the major factors of rotational speed n, pressure p, and the medium viscosity v.

1.1转速n的影响:

螺杆泵(高温双螺杆泵,大流量双螺杆泵)在工作时,两螺杆及衬套之间形成密封腔,螺杆每转动一周便由进口向出口移出一个密封腔,即一个密封腔的体积的液体被排出去。理想状态下,泵内部无泄漏,那么泵的流量与转速成正比。即:Qth=n*q n----转速; q----理论排量,即泵每转一周所排出的液体体积; Qth----理论排量。

1.2压力 P的影响:

双螺杆泵(高温双螺杆泵,大流量双螺杆泵)实际工作过程中,其内部存在泄漏,也称滑移量。由于泵的密封腔有一定的间隙,且密封腔前、后存在压差 P,因此,有一部分液体回流,即存在泄漏,泄漏量用 Q表示,则Q=Qth-Q.显而易见,随着密封腔前、后压差 P升高,泄漏量 Q逐渐增大。对于不同型线和结构,影响大小也各不相同。

1.3粘度v的影响:试想:将清水和粘稠的浆糊以相同的体积从漏斗式的容器中泄漏出去。显然水比浆糊要泄漏得快。同理,对于双螺杆泵,粘度大的流体比粘度小的液体的泄漏要小,泄漏量与介质粘度有一定的比例关系。综上所述,要综合地考虑以上各种因素,通过一系列的计算才能精确地知道泵的实际流量是否符合工况要求。

2.压力 P:

与离心泵不同,双螺杆泵的工作压力 P由出口负载决定,即出口阻力来决定。出口阻力与泵的出口处的压力是匹配的,出口阻力越大,工作压力也越大。若想知道压力,则需要用流体力学的知识对出口阻力精确的计算。2. Pressure delta P:

Unlike centrifugal pump, double screw pump working pressure delta P is determined by export load, namely export resistance to decide.Export resistance is matching with the pump outlet pressure, export the resistance, the greater the pressure of work.If want to know the pressure, you may need to drag on exports by the knowledge of fluid mechanics calculations.

3.轴功率N:

双螺杆泵(高温双螺杆泵,大流量双螺杆泵)的轴功率分为两部分,即:Nth----液压功率,即压力液体的能量; Nr----摩擦功率。3. The shaft power N:

Double screw pump (high temperature double screw pump, large flow of double screw pump) of the shaft power is divided into two parts, i.e., the Nth, hydraulic power, namely of liquid pressure energy;Nr - friction power.

对于确定的压力和流量,其液压功率是一定的,因此影响轴功率的因素为摩擦率Nr。

摩擦功率是由于运动部件的摩擦而消耗的那部分功率。这些摩擦功率显然是随着工作压差的增加而增加的,并且介质粘度的增加也会引起液体摩擦功率的增加。

由此,泵的轴功率除了液压功率外,其中摩擦功率随介质粘度及工作压力而增加,因此在选择配套电机时,介质的粘度也是一个非常重要的参考数据。尤其在输送高粘度介质时,需要作比较精确的计算。Thus, the pump shaft power in addition to the hydraulic power, the friction power increases with medium viscosity and the pressure of work, therefore, when choosing motor medium viscosity is also a very important reference data.Especially in transport high viscosity medium, the need for accurate calculation.

在计算功率后,选择配套电机时应遵照样本表格中所规定的有关规定。

N(KW) N10 10 < N50 N > 50 N > 100 K 1.5 1.25 1.15 1.1 Nm=N.K Nm----电机功率N----轴功率K----功率储备系数

4.吸上性能的计算及选择 :泵(高温双螺杆泵,大流量双螺杆泵)工作分为以下几个阶段:4. On the absorption performance of calculation and selection: pump (high temperature double screw pump, large flow of double screw pump) work is divided into the following stages:

4.1吸入,此时液体连续不断地沿吸入管道移动;the liquid move continuously along the suction piping;

4.2旋转的螺杆把能量传给工作液体;rotary screw liquid energy to work;

4.3压出,此时液体带有克服压出管道系统所有阻力所必需的压力从泵中排出。pressure, the liquid with necessary to overcome all delivery pipeline system pressure from the eduction in pump.

在 上三个阶段中,最为重要的阶段是必须保证泵的吸上条件,泵才能正常工作,这是泵工作的重要条件,否则就会发生气蚀,即引起振动,噪音等问题。In the above three stages, the most important stage is must ensure that the suction on the condition of the pump, pump can work normally, this is the important condition of pump work, otherwise cavitation occurs, which cause vibration, noise and other issues.

立式双螺杆泵V2.1ZK34Z1M1W73配2.2kw-4电机做原料油卸车泵,原料油输送泵

5.汽蚀余量的计算:The calculation of NPSH:

泵的汽蚀余量NPSHr与泵的转速n,导程h以及泵所输送介质的粘度v等因素都有关系,对我厂引进的Bornemann双螺杆泵用以下公式计算:NPSHr=(1.5+0.253VF 1.84345+0.0572VF 1.55)*v 0.4146 VF----轴向流速,VF=n*h/60(m/s); n----转速(r/min); h----导程(m); v----工作粘度(°E)。 由此可见,泵的NPSHr是随VF,v的增大而增大。因此在吸入条件不好的情况下,宜选择小导程的双螺杆泵。这在选型时是很重要的。 Pump NPSH NPSHr and pump speed n, lead h and the medium viscosity v pump etc have relations, to my factory to introduce Bornemann double screw pump with the following formula: NPSHr = 1.5 (1.5 + 0.253 + 0.0572 0.253 VF VF) * v 0.4146 VF - axial velocity, VF = n * h / 60 (m/s);N - speed (r/min);H - lead (m);V - work viscosity (°E).Pump NPSHr is, therefore, with the VF, v increases.So in the case of suction condition is bad, should choose small lead of double screw pump.This when selection is very important.

5.1装置汽蚀余量NPSHa的计算,这里不再阐述。

5.2想要保持泵正常工作,即不发生汽蚀、振动等问题,必须保证以下条件:NPSHa > NPSHr这即是泵的吸入条件。to keep the normal work of the pump, that is, do not produce the problem such as cavitation, vibration, must ensure that the following conditions: NPSHa > NPSHr this is pump suction conditions.

6.双螺杆泵(高温双螺杆泵,大流量双螺杆泵)的转速选择:Double screw pump (high temperature double screw pump, large flow of double screw pump) the speed of choice:

选择不同的转速常牵涉以下问题:Choose a different speed often involve the following questions:

6.1通过选择合适的泵转速,以达到适当的性能参数如流量等。by selecting the appropriate pump rotation speed, in order to achieve the appropriate performance parameters such as flow rate, etc.

6.2随着粘度的不同,泵的转速亦应有所改变。as the viscosity, the speed of the pump should also be changed.

对于Boremann双螺杆泵,粘度的变化是决定转速的主要条件,随着粘度的增大,允许转速也越低。For Boremann double screw pump, the change of viscosity is the main condition of decision speed, with the increase of viscosity, allow rotation speed is lower.

转速的选择实质也是吸上性能的问题,尤其是在高粘度的情况下,如果转速选得过高,就会引起吸入不足,从而产生噪音和振动等问题。因此务必遵照有关原则选择转速。Speed selection essence is also on the absorption performance problems, especially in the case of high viscosity, if speed selected too high, it will cause insufficient suction, so as to produce the problem such as noise and vibration.So be sure to follow relevant principles to choose speed.

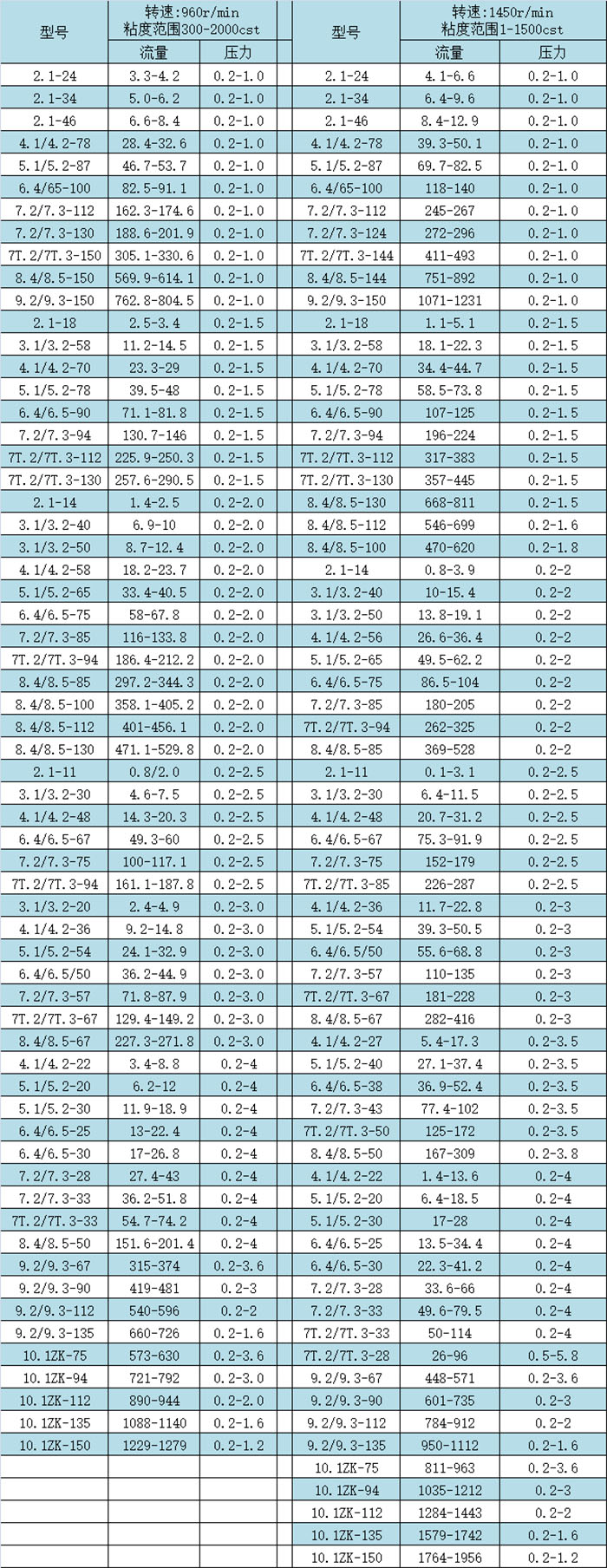

双螺杆泵性能参数表:

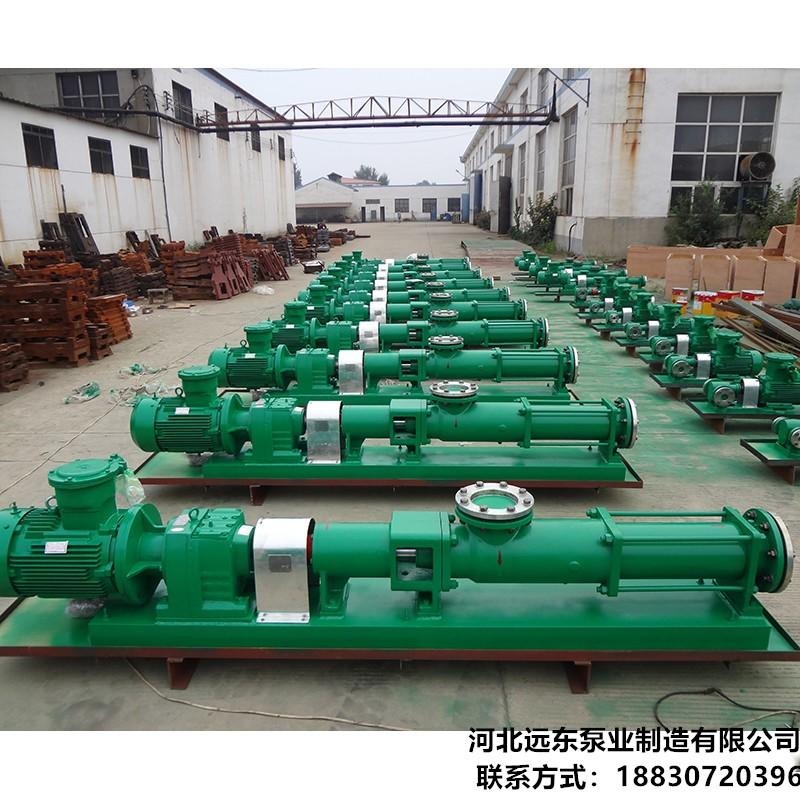

双螺杆泵产品图片:

立式双螺杆泵V2.1ZK34Z1M1W73配2.2kw-4电机做原料油卸车泵,原料油输送泵

- 产品参数

- 图文介绍

- 企业简介

- 企业地址