-

弘昇厂家代理Ni102纯镍焊条 ENi-1镍基合金电焊条

¥45.00

弘昇厂家代理Ni102纯镍焊条 ENi-1镍基合金电焊条

¥45.00 -

泰克罗伊ERNiCrMo-4镍基焊丝 Ni276镍铬钼合金焊丝

¥45.00

泰克罗伊ERNiCrMo-4镍基焊丝 Ni276镍铬钼合金焊丝

¥45.00 -

CMA-96日本神钢焊条 进口E8016-B2耐热钢电焊条

¥45.00

CMA-96日本神钢焊条 进口E8016-B2耐热钢电焊条

¥45.00 -

代理进口ENi-1镍基焊条 ENi2061镍基合金焊条

¥45.00

代理进口ENi-1镍基焊条 ENi2061镍基合金焊条

¥45.00 -

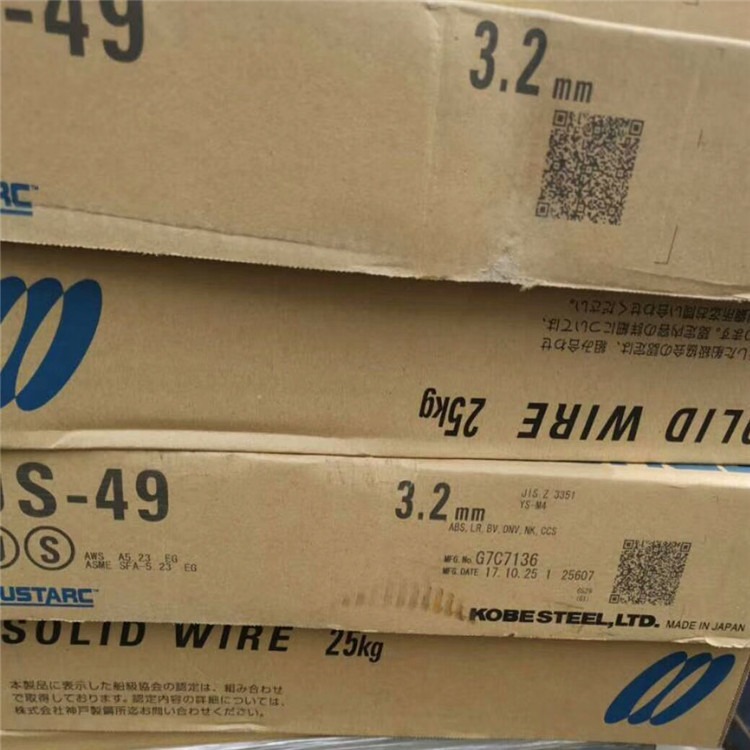

原装日本神钢 CMA-106 E9016-B3低合金耐热钢焊条

¥45.00

原装日本神钢 CMA-106 E9016-B3低合金耐热钢焊条

¥45.00

- 产品参数

- 图文介绍

- 企业简介

- 企业地址

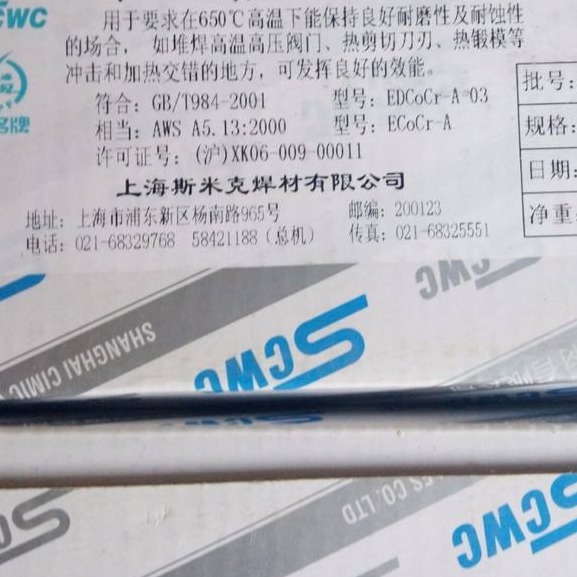

上海斯米克铜焊丝 S229钎焊铜合金焊丝 Cu55 Ni6 Mn4斯米克焊丝上海斯米克S229铜焊丝 Cu55 Ni6 Mn4钎焊铜合金焊丝1.氩弧焊时建议用大流量、低流速的气流,以保证焊接熔池得到良好的保护。

2.薄板采用I型坡口;较厚的板采用V型或X型坡口,需加衬垫。

3.好采用平焊位置焊接。在有脉冲电弧焊设备和焊工操作技术良好的情况下,也可进行其他位置焊接。

4.不推荐把这种焊丝用于气焊,因为在焊接熔池中会有铝的氧化物存在,影响焊缝质量。

5.将焊接部位的锈层、湿气、油污、灰尘等确实除净。铜及铜合金焊丝的用途有三种: 首先是焊接铜及铜合金, 用于铜及 铜合金连接; 其次由于具有良好的耐蚀性和耐磨性, 常用于堆焊耐金属 间摩擦的部件(如轴瓦、 低压阀门密封面) 和耐海水腐蚀工件(如螺旋 桨) 等; 此外, 更广泛的是用于钎焊钢、 硬质合金工具等。

铜及铜合金焊丝可用熔化极氩弧焊(MIG焊) 、 钨极氩弧焊(TIG 焊) 、 气焊及等离子弧焊等方法施焊。

钨极氩弧焊(TIG焊) 通常采用直流正接方法, 熔化极氩弧焊(MIG 焊) 通常采用直流反接方法。

Copper alloys

铜

合

金 | S 201 | Sn1 Si0.3Mn0.3 | Good mechanical properties and crack resistance. Gas welding and argon arc welding of red copper. | ERCu |

S 211 | Si3 Mn1 | Good mechanical properties. Argon arc welding of copper alloys and MIG brazing of steel. | ERCuSi-Al | |

S 212 | Sn5 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuSn-A | |

S 213 | Sn8 Cu Rem. | Wear resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuSn-C | |

S 214 | Al7.5 Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuAl-A1 | |

S 215 | Al9 Cu Rem. | Wear and corrosion resistance. Argon arc welding of copper alloys and surfacing of steel. | ERCuAl-A2 | |

S 221 | Cu60 Sn1 Si0.3 | Melting point is about 890℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | ||

S 221F | Cu60 Sn1 Si 0.3 | S221 welding rod coated with flux. | ||

S 222 | Cu58Sn0.9Si0.1 | Melting point is about 880℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | RBCuZn-C | |

S 222F | Cu58Sn0.9Si0.1 | S222 welding rod coated with flux. | RBCuZn-C | |

S 223 | Cu59 Sn0.6 | Melting point is about 900℃. Braze welding of copper, steel and cast iron. | RBCuZn-A | |

S 224 | Cu62 Si0.5 | Melting point is about 905℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | ||

Copper 铜

合

金 | S 225 | Cu48 Ni10 | Melting point is about 935℃ and high strength. Braze welding of steel, nickel and carbide alloys. | RBCuZn-D |

S 225F | Cu48 Ni10 | S225 welding rod coated with flux. | RBCuZn-D | |

S 226 | Cu60 Sn0.3 | Melting point is about 900℃. Gas welding of brass, also braze welding of copper, steel and cast iron. | ||

S 227 | Cu58Sn0.9Ni0.5 | Melting point is about 880℃. Gas welding and carbon arc welding of brass, also braze welding of copper, steel and cast iron. | RBCuZn-B | |

S 229 | Cu55 Ni6 Mn4 | Melting point is about 920℃, high strength. Braze welding of steel, nickel and hard carbide. | ||

Aluminum alloys

铝

合

金 | S 301 | Al≥99.5 | Good ductility and corrosion resistance. Gas welding and argon arc welding of pure aluminum. | ER1100 |

S 311 | Si5 Al Rem. | Corrosion resistance, wide range of usage. Gas welding and argon arc welding of aluminum alloys other than high magnesium alloys. | ER4043 | |

S 321 | Mn1.3 Al Rem. | Good corrosion resistance, weldability and ductility. Gas welding and argon arc welding of aluminum alloys. | ||

S 331 | Mg5 Mn0.4 | Corrosion resistance and high strength. Argon arc welding of aluminum alloys. | ER5183 |

-

四川大西洋 ER309 不锈钢氩弧焊丝 耐蚀性好电弧稳定¥290.00

四川大西洋 ER309 不锈钢氩弧焊丝 耐蚀性好电弧稳定¥290.00 -

弘昇代理德国蒂森伯乐 E8010管道焊条¥45.00

弘昇代理德国蒂森伯乐 E8010管道焊条¥45.00 -

奥地利伯乐 E8010纤维素管道焊条总代理¥45.00

奥地利伯乐 E8010纤维素管道焊条总代理¥45.00 -

上海电力 E8018-B2低氢钾型药皮耐热钢焊条¥29.00

上海电力 E8018-B2低氢钾型药皮耐热钢焊条¥29.00 -

供应正品上海电力E81T1-B2耐热钢焊丝¥290.00

供应正品上海电力E81T1-B2耐热钢焊丝¥290.00 -

东海溶液TM-2000H堆焊冷作模具焊条¥65.00

东海溶液TM-2000H堆焊冷作模具焊条¥65.00 -

供应金桥A402 钛钙型不锈钢焊条 耐高温E310-16¥65.00

供应金桥A402 钛钙型不锈钢焊条 耐高温E310-16¥65.00 -

德国UTP C276 ERNiCrMo-4耐腐蚀镍基合金焊丝¥290.00

德国UTP C276 ERNiCrMo-4耐腐蚀镍基合金焊丝¥290.00

-

弘昇销售 北京金威 ER309LSi不锈钢焊丝 2.4mm

¥45.00

弘昇销售 北京金威 ER309LSi不锈钢焊丝 2.4mm

¥45.00 -

现货销售大西洋 ER310 25Cr20Ni耐高温不锈钢氩弧焊丝

¥45.00

现货销售大西洋 ER310 25Cr20Ni耐高温不锈钢氩弧焊丝

¥45.00 -

泰克罗伊Tech-Rod 182 进口ENiCrFe-3镍铬合金焊条

¥45.00

泰克罗伊Tech-Rod 182 进口ENiCrFe-3镍铬合金焊条

¥45.00 -

原装进口ER5556铝镁合金焊丝 焊缝成形美观细腻

¥45.00

原装进口ER5556铝镁合金焊丝 焊缝成形美观细腻

¥45.00 -

天津金桥ER316 直条不锈钢焊丝 0Cr18Ni12Mo2钢

¥45.00

天津金桥ER316 直条不锈钢焊丝 0Cr18Ni12Mo2钢

¥45.00

- 产品参数

- 图文介绍

- 企业简介

- 企业地址